- Joined

- Dec 1, 2016

- Messages

- 5,136

- Points

- 728

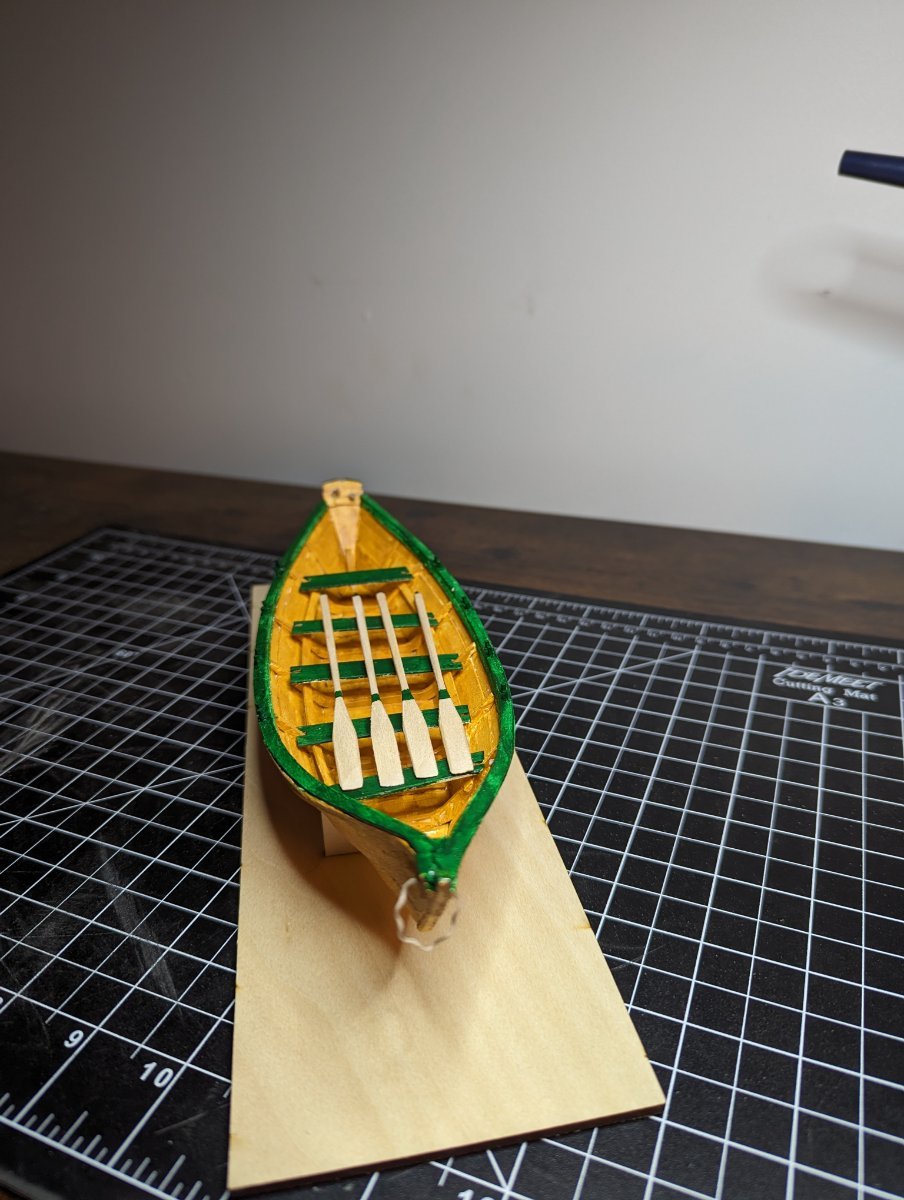

I think Dave, the haws hole on the Sheer Strake, and the caprail plank should be the indication of the bow. But it would be nice if we had an arrow engraved toward the bow,

you would think so but looking at a picture of the bow in the instructions there is no haws hole so you would naturally put that hole at the stern.