Yep, I also use heavily diluted Brass Black (more water than Caseys), this way it works the best, it is a slow-curing process. However, I never used the same solution twice. It is a chemical reaction between the brass and Casey's so I thought the resulting solution was not good. Am I mistaken?I think the magic happens when you dilute the Caseys and allow the burnishing to take more time. Again, still learning...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Kingfisher 1770 1:48 POF

- Thread starter dockattner

- Start date

- Watchers 112

I read it somewhere and it seems to work fine. The same liquid has now been used maybe 10 times with little change in efficacy...Yep, I also use heavily diluted Brass Black (more water than Caseys), this way it works the best, it is a slow-curing process. However, I never used the same solution twice. It is a chemical reaction between the brass and Casey's so I thought the resulting solution was not good. Am I mistaken?

Absolutely clean work, you did a great job on the rudder with all the brass work and is absolutely impressive.

That is an awesome rudder.

Very impressive, an excellent example. Bookmarked it.

Very impressive, an excellent example. Bookmarked it.

Great looking hinges Paul! Glad to see you try and master welding, it is satisfying when it works.

Geoff, Ron, Tobias, Herman, Daniel and Ken - thanks for posting! It makes me want to solder more stuff  .

.

.

.If you can find stainless steel T pins the solder won't stick to them.

- Joined

- Nov 10, 2020

- Messages

- 134

- Points

- 253

No Problem at all. I have made many mistakes and ommissions on my Pegasus swan class build.Hi @trussben,

I re-read my response to you, and I fear I might have come across as dismissive of your very accurate/helpful/well-informed post. When I was building the well house I "over shaped" the part that merges with the shot locker. I had already invested quite a bit of time on that part and when I recognized that I would need to place the hinges in the wrong place I chose to just accept the mistake and carry on. I am not attempting to build the perfect TFFM swan class ship.

BUT: if I was trying to build the perfect TFFM swan class ship your post would have saved the day! So, THANK YOU for your keen attention to detail and feeling welcome to offer a suggestion for improving this build. I do rely on people like you who have far more experience and knowledge than I do to keep my project on track. While I won't be correcting this error, I have been correcting other mistakes pointed out by forum members. Keep the suggestions coming! And I apologize for the brevity of my original post.

I am really impressed with your rudder work Paul. I struggled making pintles and gudgeons from scratch but you have, once again, shown how it can be done to such an incredibly high standard. Wonderful job!

Hi Paul,Hello Michael,

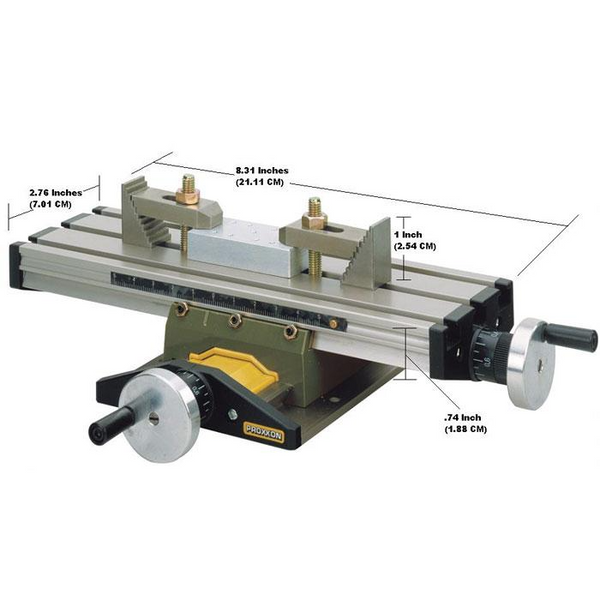

Q1: this is the Compound Table that comes with the Proxxon Mill - though I purchased a second one to also use with a small drill stand. It is designed to fit onto Proxxon machines/tools.

MICRO Compound Table KT 70

For precise milling, boring, drilling or grinding operations as well as positioning. The optimal attachment when working with the Drill Stand MB 140/S, the Bench Drill Machine TBM 115 or the Machine Vice MS 4. One set of step clamps and clamping accessories are included. Technical data:Table...proxxon-us-shop.com

Q2: I did some initial shaping using a disc sander. The rest was done with files.

Q3: Casey's Brass Black

Q4: This one is more a work in progress for me. I am very familiar with the frustration of getting a powdery black layer that flakes off. My current approach is as follows (though I suspect it will change as I learn more). First, I thoroughly clean the parts (rotary tool, sandpaper, etc.) and then I drown the parts in white vinegar (30 - 60 minutes seems about right) and after this the parts must not be touched by fingers - only tweezers. Then I drown the part in Brass Black that has been quite diluted (not exactly sure of the formula - it is at least 50% water right now, maybe as much as 80%???) I use the same Brass Black over and over. In it's diluted state the blackening/burnishing takes a bit longer (maybe 60 seconds). Rinse off the part in running water and set on a paper towel to dry. I then wipe down the part using a soft cloth or Q-tip (there will be a fine powder on it) and assess. You can go back into the Brass Black if you want it darker. I think the magic happens when you dilute the Caseys and allow the burnishing to take more time. Again, still learning...

I am starting to notice that every time I read your build updates, I find myself wanting to go and buy more equipment and tools.

I think maybe if I use the same tools as Paul, I too can make such beautiful models and parts. Then I realise that I need to buy your ability, which alas is not for sale.

Anyway, I will just have to be happy with some more tools.

Thanks for you detailed replies.

michael

Where did you get your bits for drilling the holes, Paul? The holes look very small. And what size nails did you use?Next, I needed to drill holes for the bolts that would hold the straps to the rudder and the hull. To that end I made a little jig:

View attachment 426367

View attachment 426368

I then used epoxy to add the pins to the pintles (I could have soldered these pins but that would have required a lower melting temperature solder (than I had used previously) and I doubted I could pull that off):

View attachment 426369

View attachment 426370

That done, I burnished/blackened the parts and completed the rudder side of the transaction:

View attachment 426357

View attachment 426358

View attachment 426359

View attachment 426360

View attachment 426361

View attachment 426362

View attachment 426364

View attachment 426365

View attachment 426366

And just in case you think this was a linear experience...I learned that brass can melt...and that it's possible to solder the pins you are using to hold pieces into place onto (inside) the parts you are soldering...

View attachment 426371

I feel blessed that you would visit on occasion!

- Joined

- Aug 8, 2019

- Messages

- 4,253

- Points

- 688

What do you mean with casey's?It is a chemical reaction between the brass and Casey's

- Joined

- Aug 8, 2019

- Messages

- 4,253

- Points

- 688

Thank you, I have this in stock. So next time when I have to blackening brass I give it a try to dilute the casey. Is there a special amount? 1 part on 100 for example?Birchwood Casey’s is a brand of Brass blackening solution for firearms. It’s the blue bottle with white lid.

There are other brands available, but Casey’s seems to be popular and available.

View attachment 427375

Good afternoon Paul. No comment you have received enough accolades…a standing ovation is deserved tho. Cheers Grant