I've also made progress preparing the decking planks. I had to modify the Aldi Workzone saw table as the gap around the blade was too wide to cut tiny thicknesses. They kept tearing and breaking off down beside the blade. It now works really well for a cheap saw and I have enough 1/16" x 1/4" planks to complete the gun deck. The blade is 64 tooth.

Cutting two pieces of 1/16" X 1/4" together.

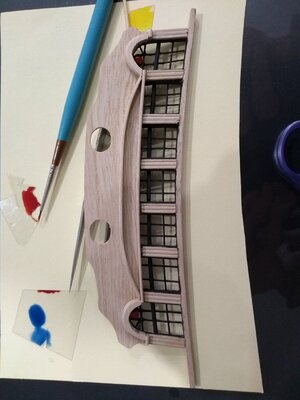

A light hand sand brings these up to standard and I'll move onto planking the gun deck after I complete the planking above the wales. Made a start today.

The paint on the wales has suffered and will have to be done again, but that will be much later.

Cutting two pieces of 1/16" X 1/4" together.

A light hand sand brings these up to standard and I'll move onto planking the gun deck after I complete the planking above the wales. Made a start today.

The paint on the wales has suffered and will have to be done again, but that will be much later.