Update 6

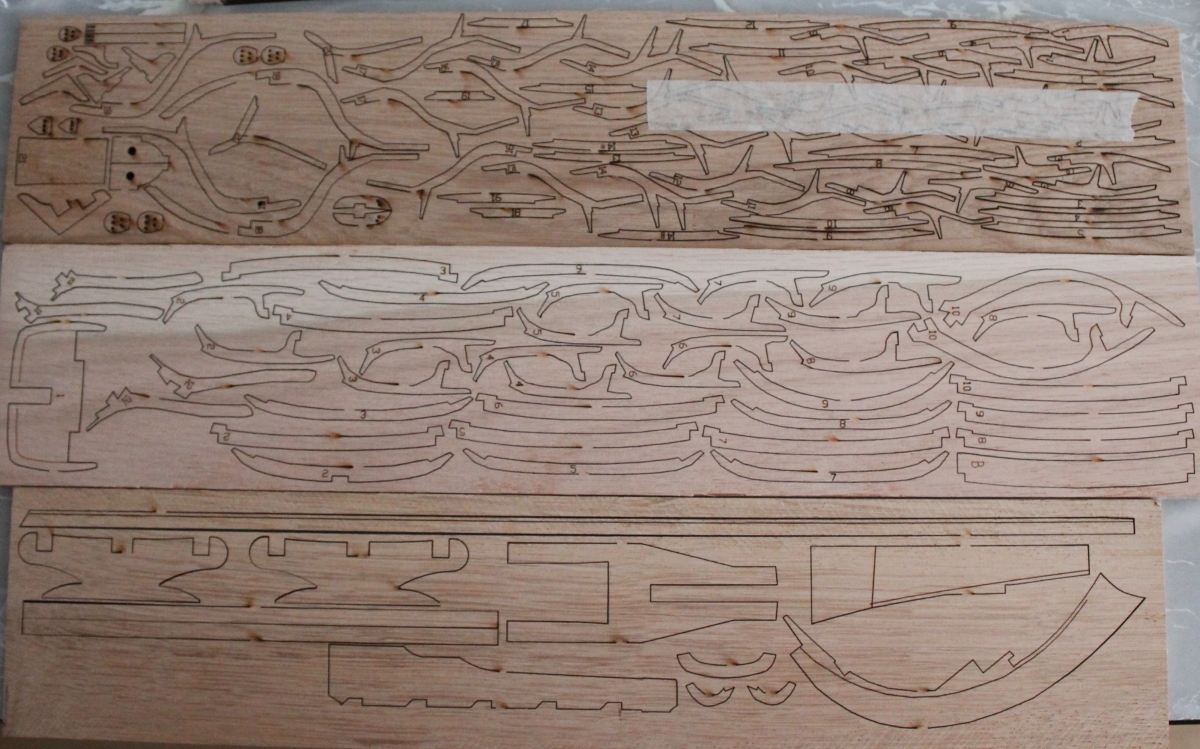

We continued planking and got as far as the MDF struts could go.

The bottom now looks like this:

And the two stem ends like this:

And these are the two sides:

When you hold the whole thing up to the light, you see a ship you shouldn't sit in if you don't want to get wet. Fortunately, I'm not turning it into a sailing model.

I'm not going to do anything about this for now, from the outside you can see it. If it becomes visible with painting we'll see then.

And on the inside it looks like this:

On the rear two squares have been glued indicating the place where there should be two loading hatches. Furthermore, the spar is also in place and to the side of it two bottom planks.

Both mast tracks are still loose.

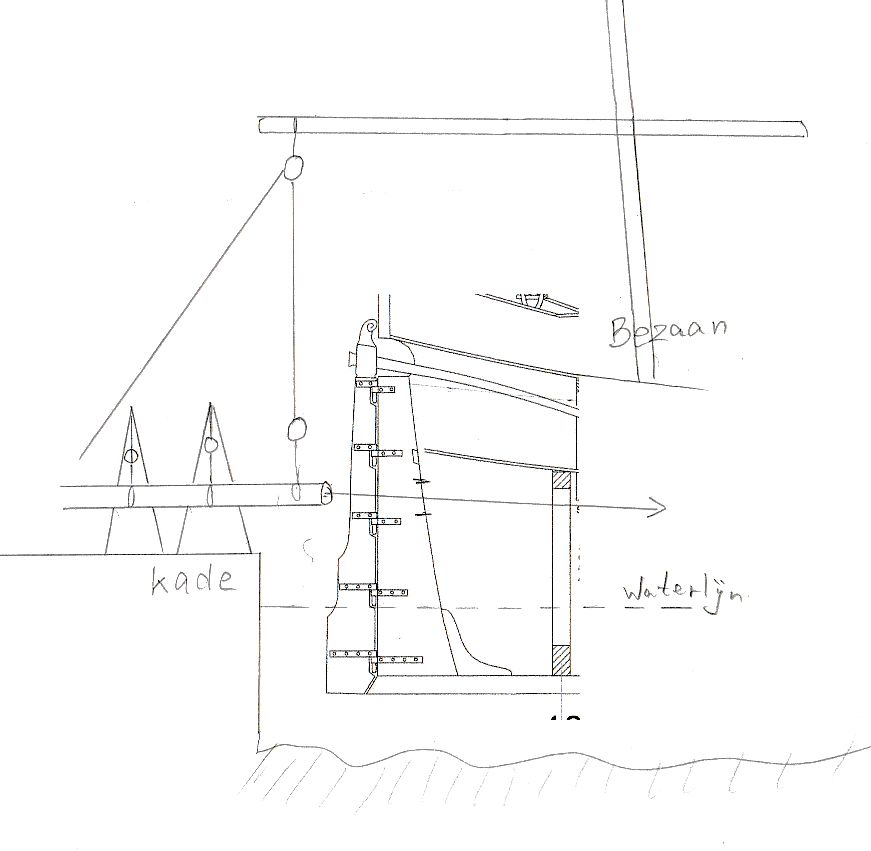

There will be four loading hatches. Two in the stern and two on the port side. If they are now loading logs hanging in the hoists, I think they will also have people inside to guide things. If you are then on the bottom and can hardly see anything to the outside, I don't think that's useful. So I imagine you want to stand right behind the hatch and be able to communicate with the people outside. Either a small platform under the loading hatches that you can stand on and look outside would be handy. So I made a small platform against the rear just below the cargo hatches with a climbing pole from the bottom.

On the left, the stern with a little platform under the loading hatches. On the right, the bow with the mast track for the jib mast. That's where the turning trusses will be.

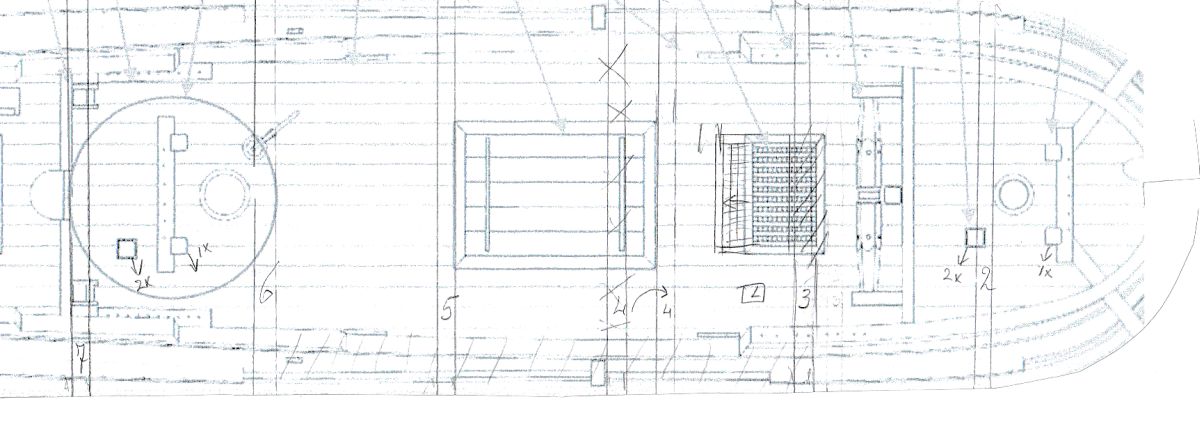

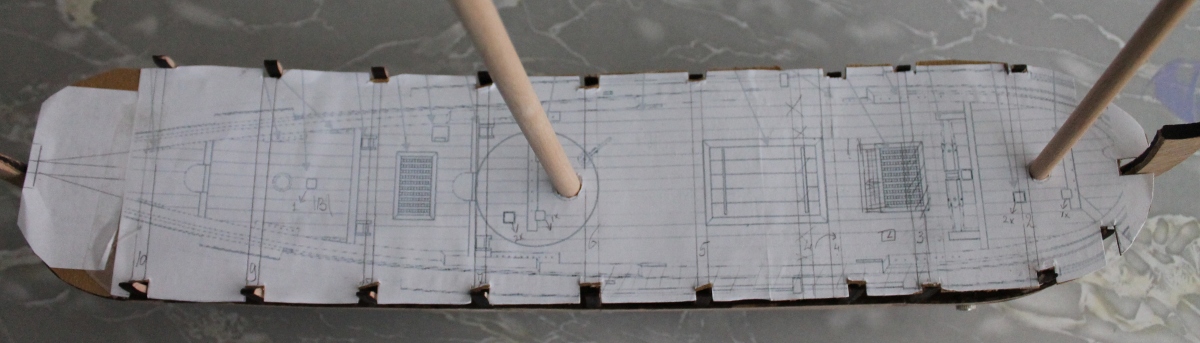

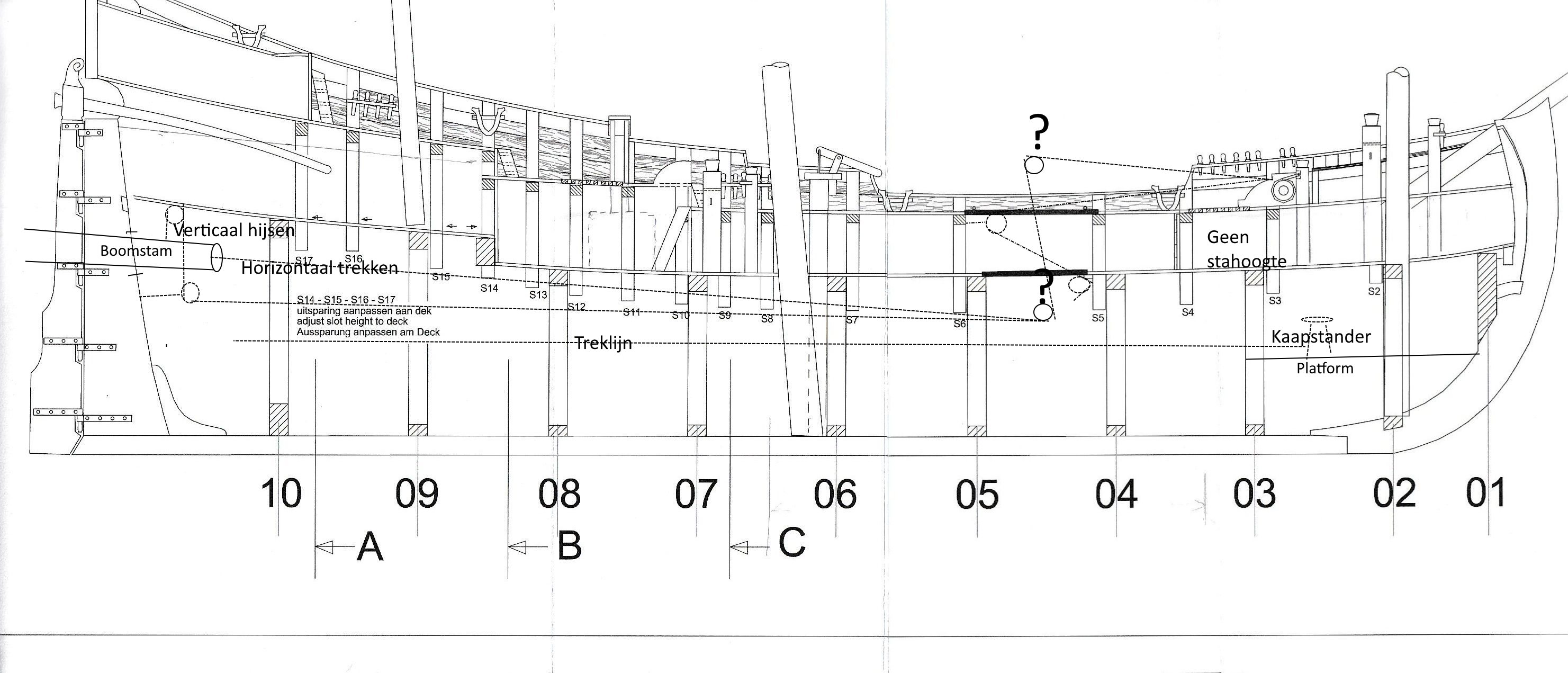

To get a good idea now of what to build on top later, I scanned the deck plan from the building description and printed it out in 1:1 scale with the model. Then I can put it on the model and see what needs to be built higher up.

Then I see that one of the lower layer deck beams with corresponding truss no 04, runs exactly under the large deck hatch. I want to leave both hatches open so that beam has to go a bit to the side.

This truss consists of three parts, the two upright parts of which I have detached and moved a bit. Through the head of the row of trusses I put a batten to determine the correct height of the relocated truss. Otherwise, I will have problems later when laying the deck.

On the heads of those trusses, deck beams will be laid for support of the deck. But I also need those deck beams to hang some lanterns (yellow LEDs) and a whole bunch of eyes for hoists.

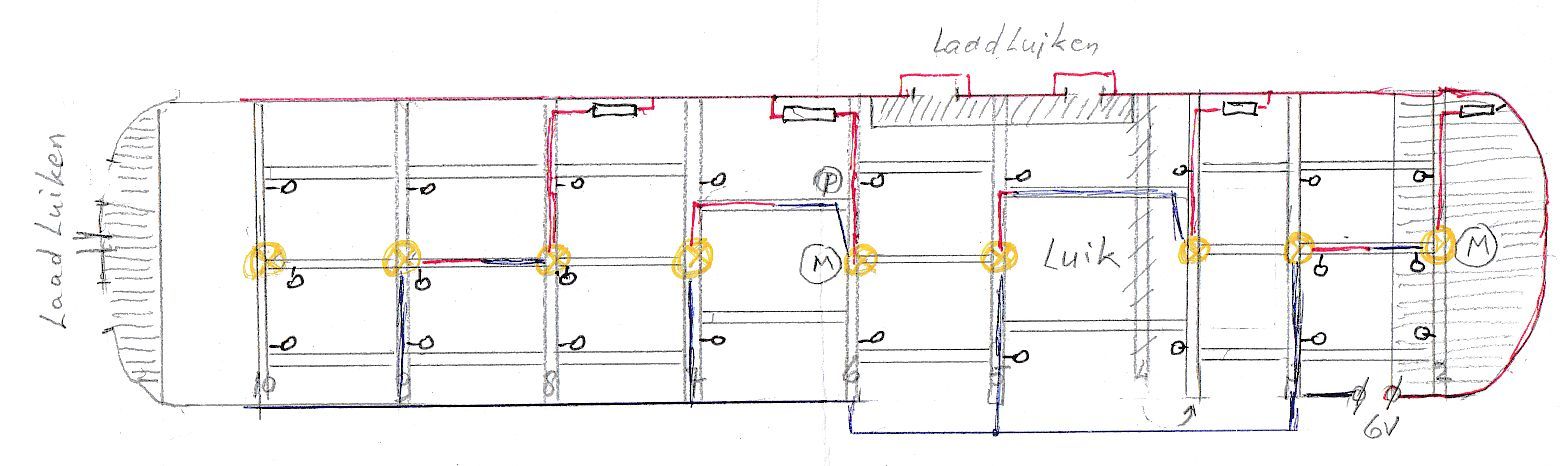

So I made a new deck plan.

Here you can see that deck beam 4 has been moved slightly forward so that the hatch is now clear. A little platform has also been drawn under the cargo hatches on the port side as well as in the bow. That will be a platform for some cargo. You can also see the locations of the yellow LEDs that will be supplied with 6 volts. The connector for this is at the bottom right.

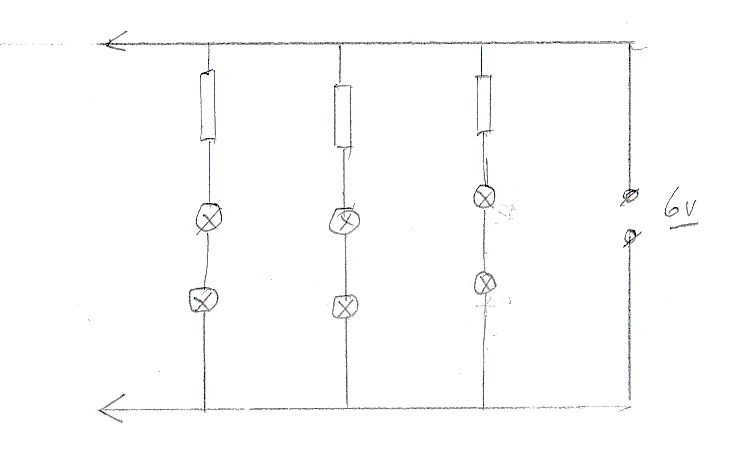

The principle diagram for the LEDs is the following:

Two LEDs in series with a resistor and that several times between the + and - of the power supply.

So there is a direct connection between the LEDs. On the deck plan, you can see that there is thus a direct wire running between the LEDs on different deck beams. That is why I am also making longitudinal beams between the deck beams where I can then hide the wiring behind. At the mast and hatch, I can only fit two elsewhere three.

There will also be double planking for the most part and I can also fit some wiring there.

To be continued.

Translated with

www.DeepL.com/Translator (free version)