- Joined

- Dec 1, 2016

- Messages

- 5,136

- Points

- 728

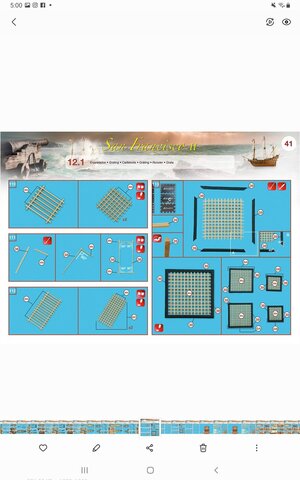

i have seen on a number of models with coamings for hatches, gradings and deck structures are done with a 45 degree angle at the corners like this.

A corner like this would pull apart and leak. Starting out i did the same thing thinking that makes a nicer corner rather than just butting the pieces together.

On real ships the corners are joined using a lap scarf and that looks like this

here are another examples in the first image you can also see the corner of the companion way with the lap scarf.

this is a correct corner joint for a coaming on a model

when planking a deck model builders will run the ends of the planking to the edge of the opening and set the coamings on top of the planking like this

hatch coamings on real ships sat on the beam and the deck planking ran up to and butted the side of the coaming. so you need to install the coamings first then lay the deck planking. Here you can see the coaming is sitting directly on the beam, there are no deck planks between the bottom of the coaming and the deck beam.

The average person viewing a model would never know the difference or ever spot such a detail, it is more a personal little detail or if you are planning on entering into competition.

A corner like this would pull apart and leak. Starting out i did the same thing thinking that makes a nicer corner rather than just butting the pieces together.

On real ships the corners are joined using a lap scarf and that looks like this

here are another examples in the first image you can also see the corner of the companion way with the lap scarf.

this is a correct corner joint for a coaming on a model

when planking a deck model builders will run the ends of the planking to the edge of the opening and set the coamings on top of the planking like this

hatch coamings on real ships sat on the beam and the deck planking ran up to and butted the side of the coaming. so you need to install the coamings first then lay the deck planking. Here you can see the coaming is sitting directly on the beam, there are no deck planks between the bottom of the coaming and the deck beam.

The average person viewing a model would never know the difference or ever spot such a detail, it is more a personal little detail or if you are planning on entering into competition.