Excellent work Francois!

Last edited:

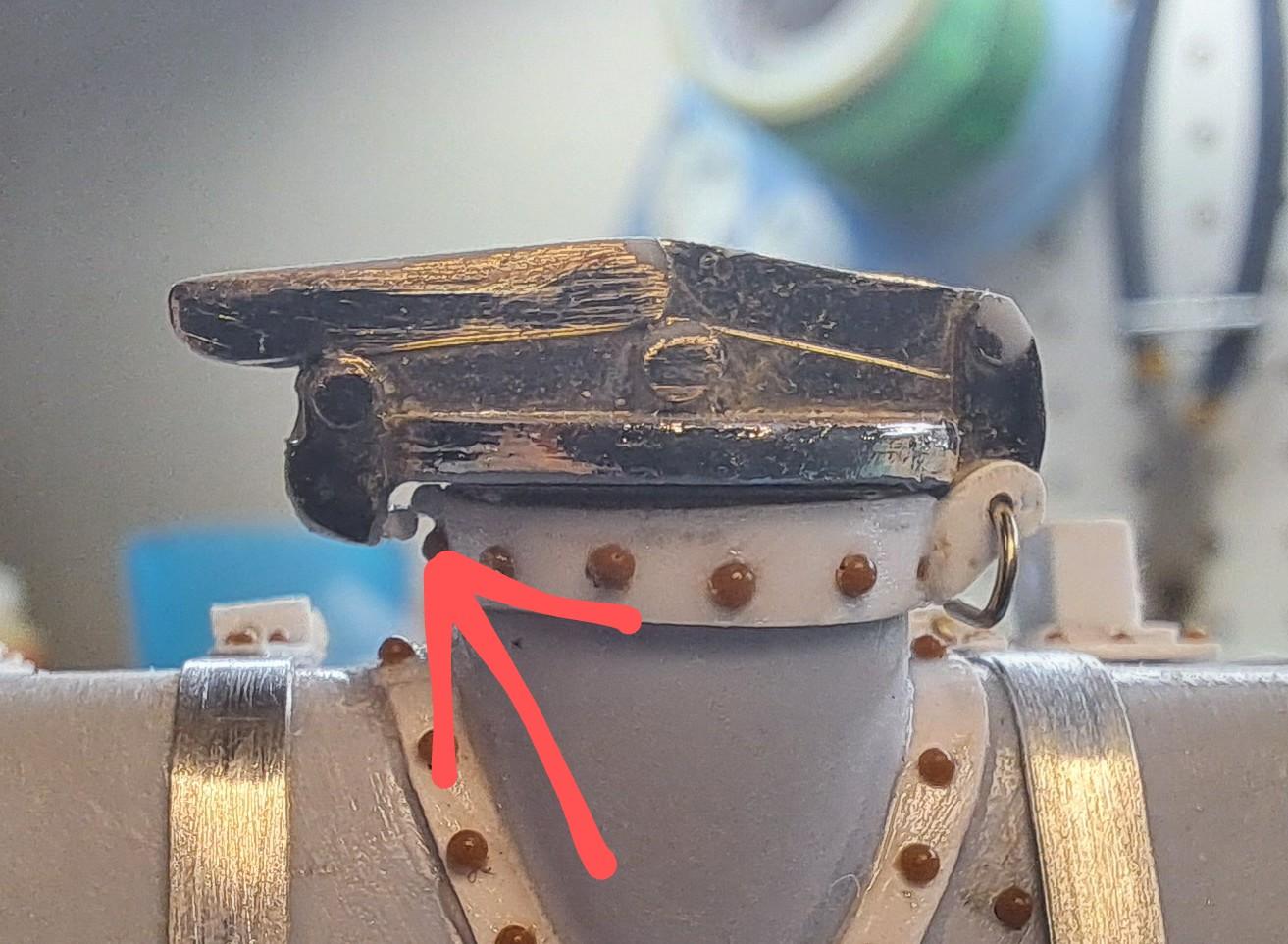

Francois, your fabrication skills are outstanding! And I appreciate how hard that is at scale. Just making plug wire looms on my build I realized that some parts are so small that you can barely handle them, which required putting the pieces in a vice so I could file and sand. So I appreciate the challenges to make these parts. Keep up the great work!Thanks! I made a trial fit of the hose clamp and support bar. Should be ok.View attachment 376551View attachment 376552

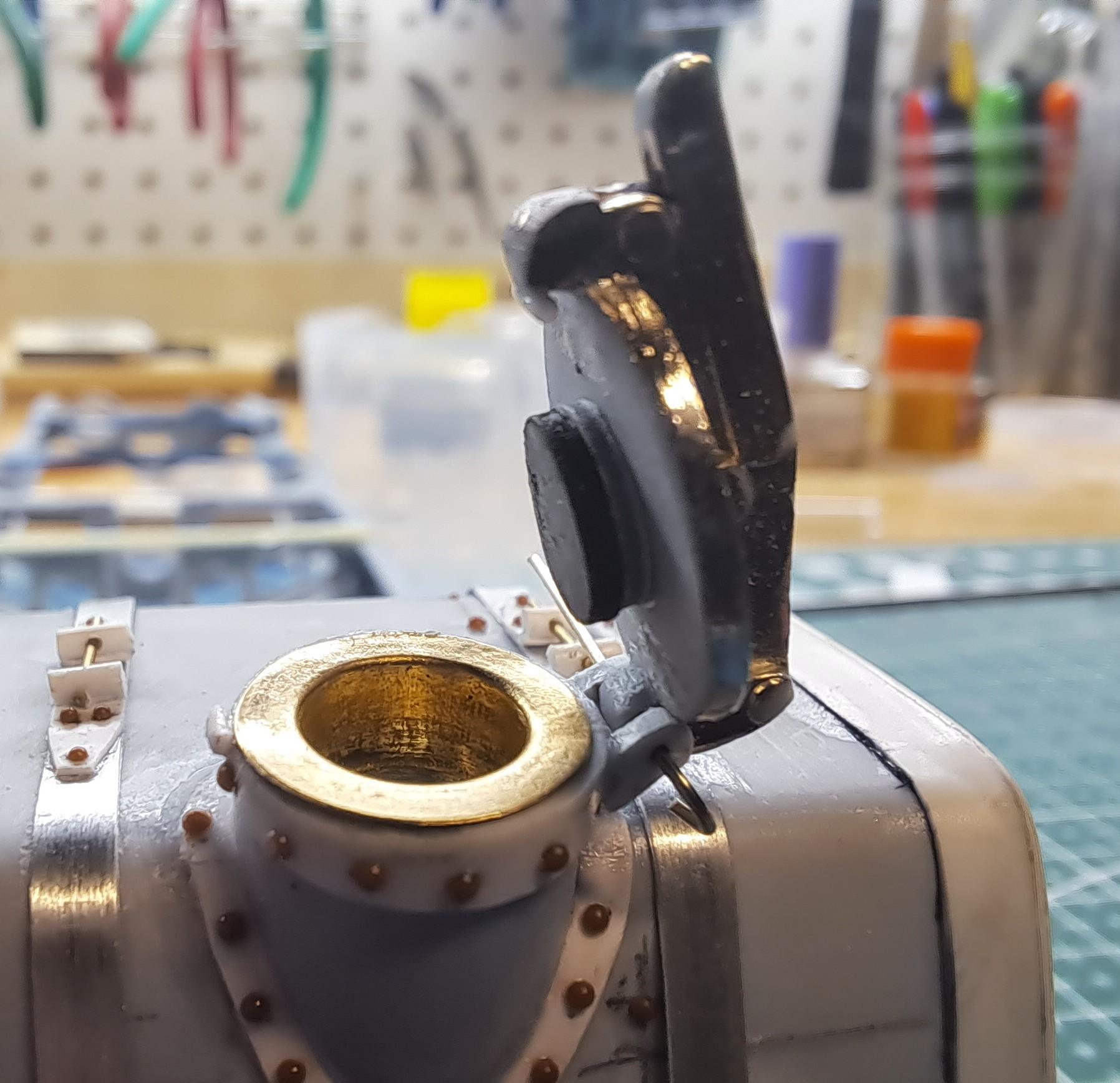

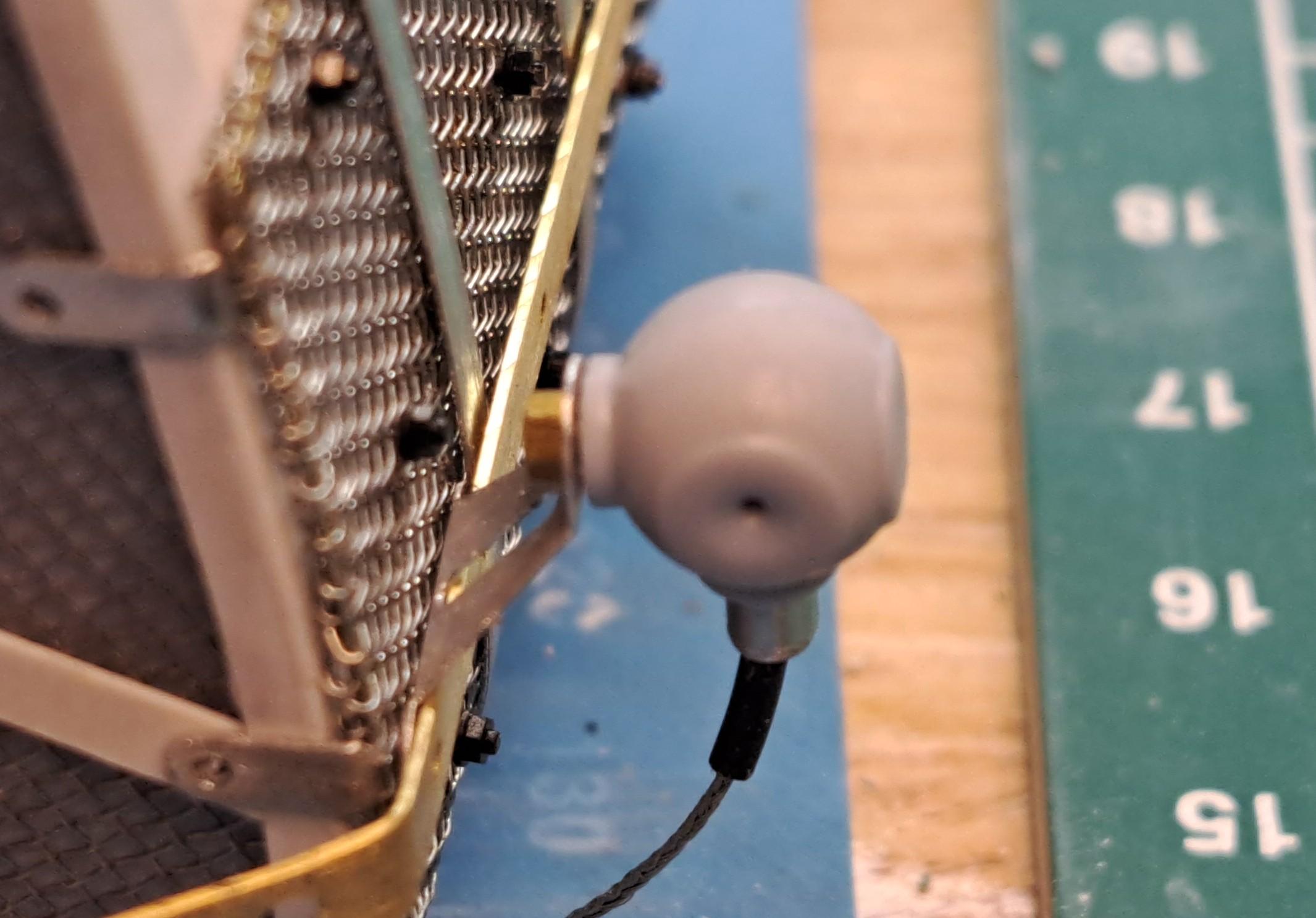

Francois, that’s a crazy gas tank as far as complexity goes! You’re doing a fantastic job detailing it, as usual!got all 4 fuel hoses done complete with a better looking petcock than my first try and splicer coupling.View attachment 376987View attachment 376988

and on tank with hose clampView attachment 376989

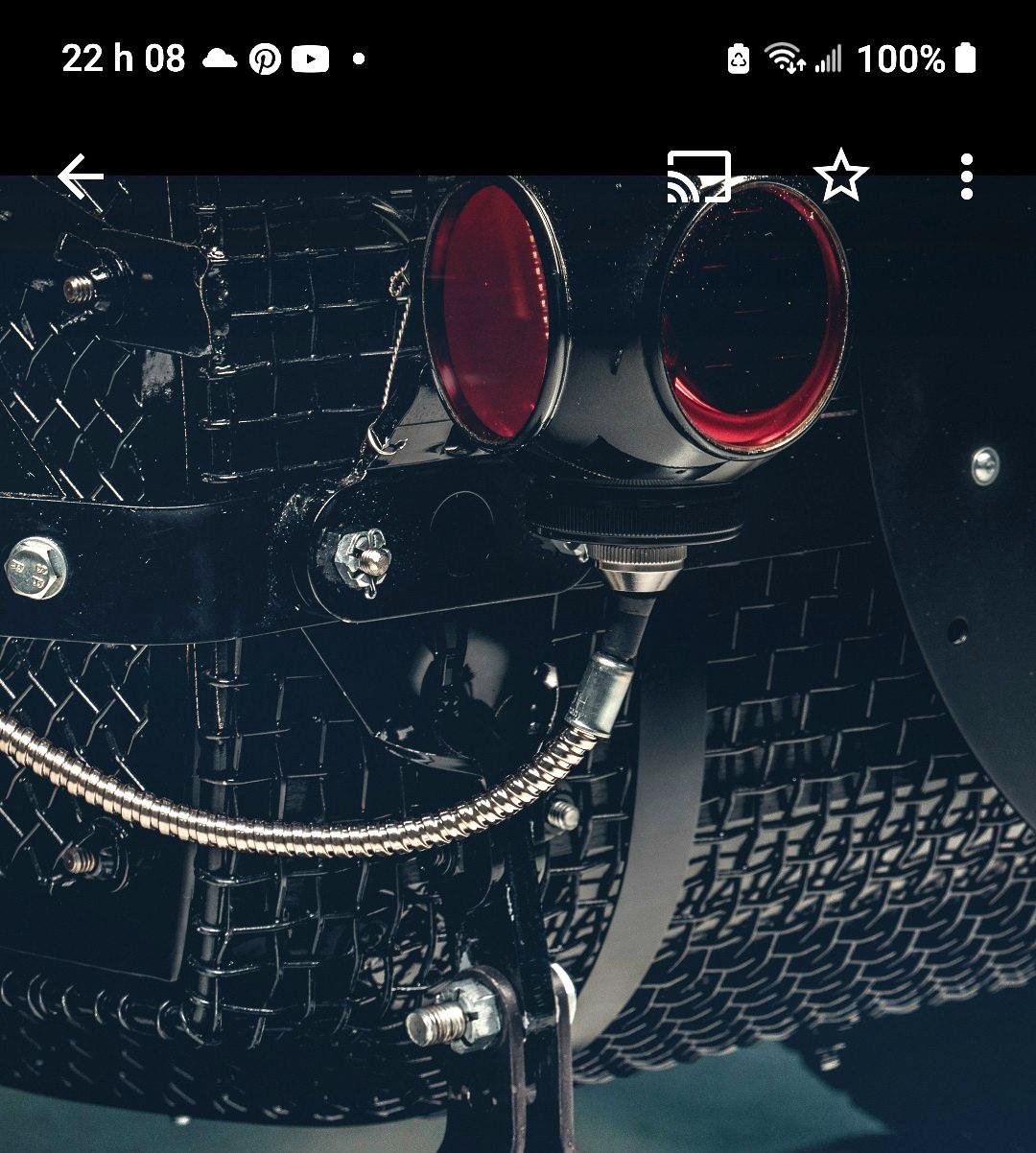

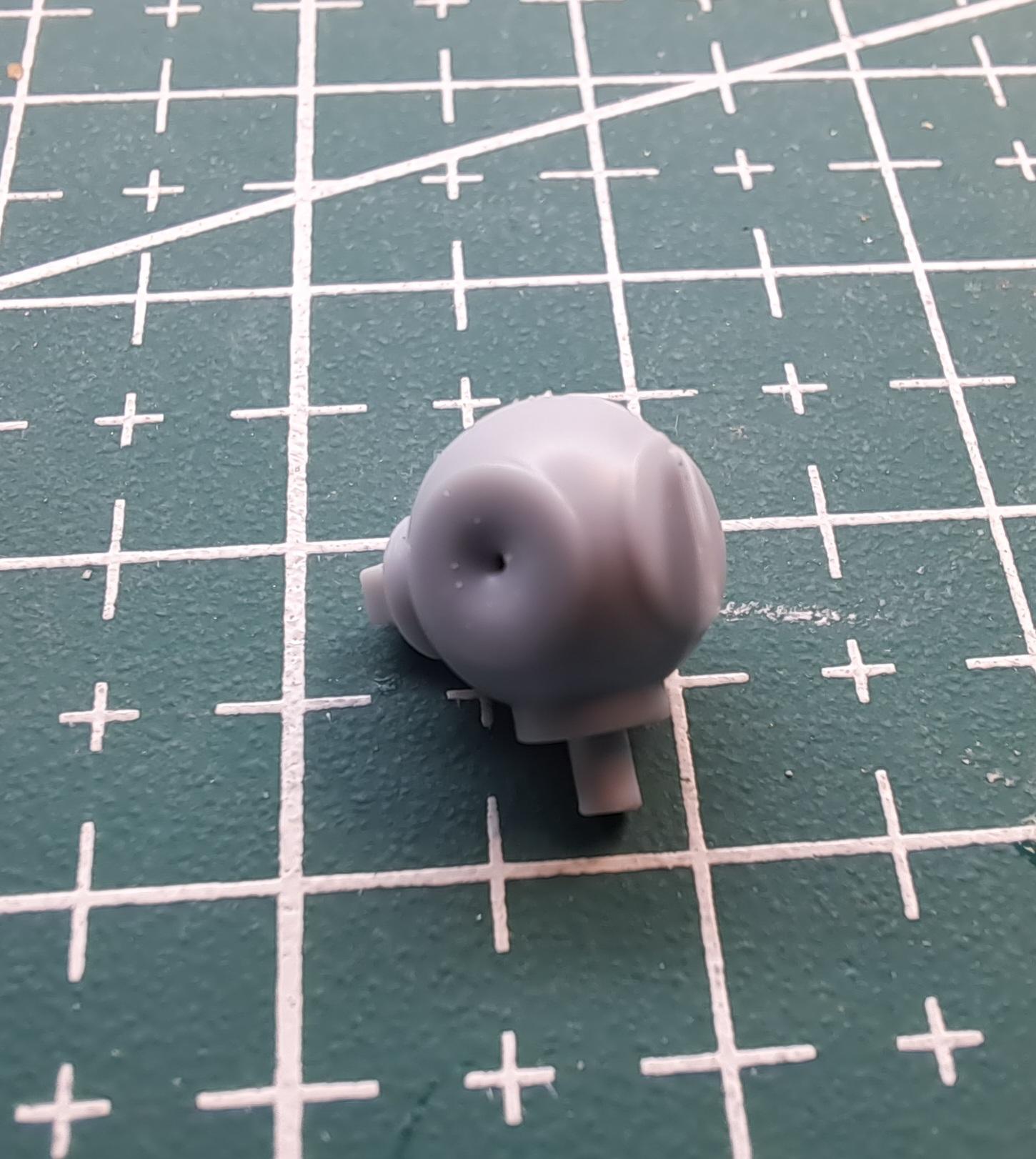

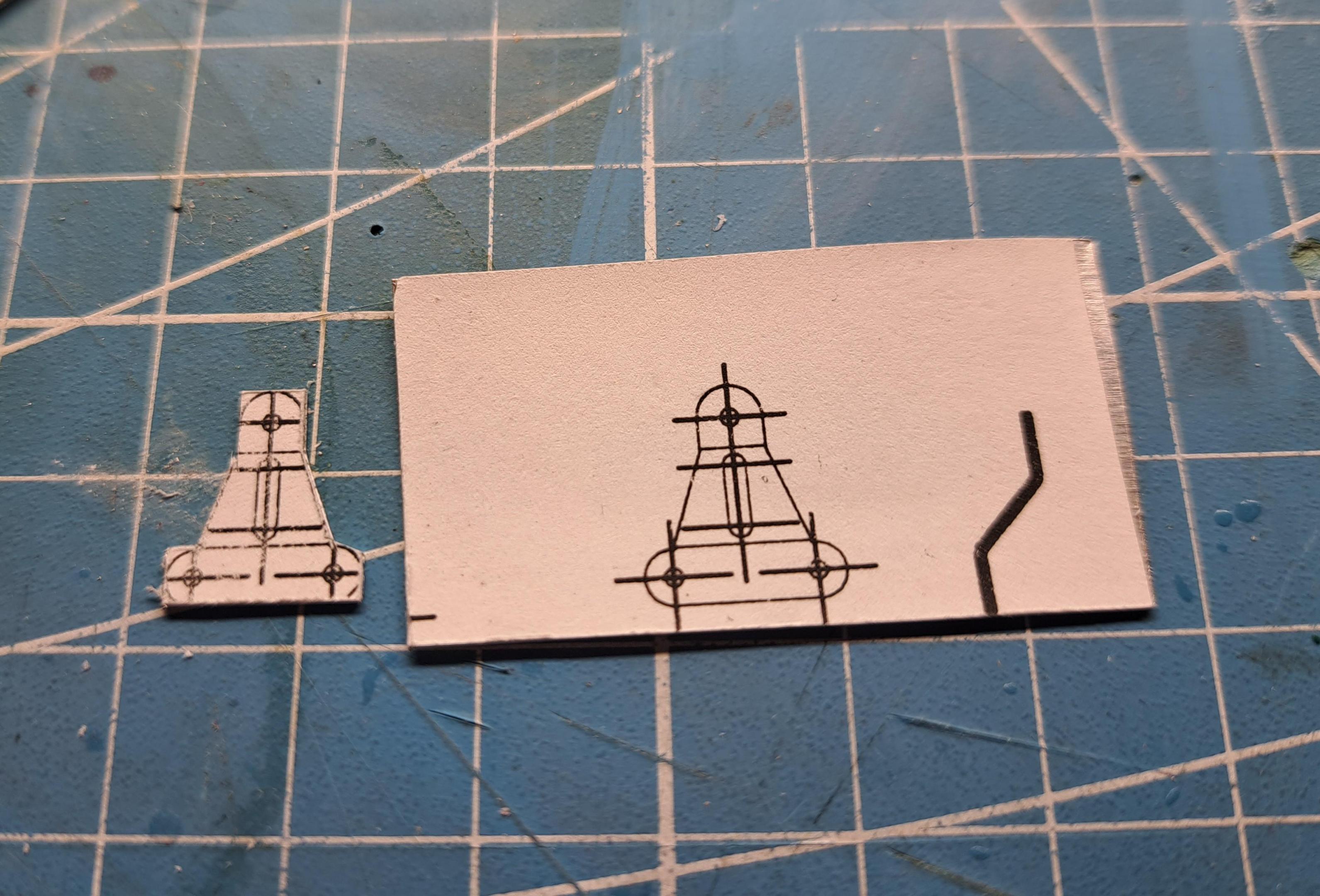

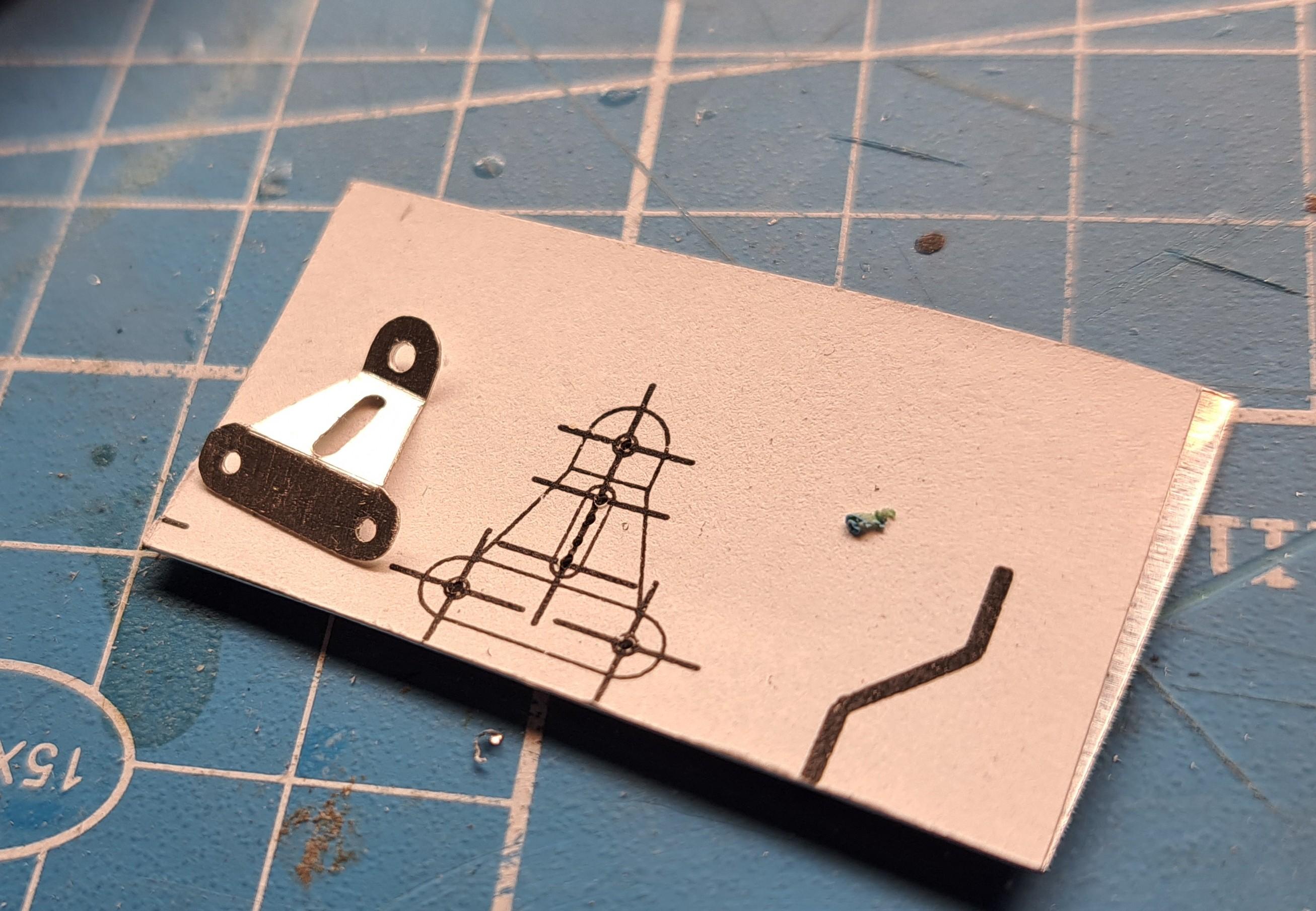

only one more detail to add to the tank before primer and paint. The wire mesh on the real tank is held in place with wingnuts screwed thru welded tabs. I tried finding 3d printed wingnuts but all l could find came from europe (so very pricey onces delivered) and I really wasn't sure that the size would be ok. So I 3d modeled a properly sized wingnut for my application and will have it printed locally.

Wingnuts on real tankView attachment 376985

tabs installedView attachment 376990

3d modeled wingnut ready for printingView attachment 376986

Thank you Francois! I have seen many builds where people put the Pocher Lotus 72 together out of the box, which still looks nice. However, in my opinion, due to all the parts being a single color, silver or black, it should be treated just like any other model, and each and every part should be painted and detailed appropriately.Thanks Dean. Aside from the actual tank itself which I sanded bare and the light fixtures that will be greatly modified, every feature currently on the tank was scratch built since the kit doesn't provide any of them and what little is there is not accurate to my ref car. Yes, I trully enjoy this and I like to push the enveloppe so to speak. This also applied when I used to design custom automation machinerie, I rarely did the same thing twice and was always thinking out of the box. Maybe that's why I don't work anymore, my designs where always very nice looking and exotic but also very expensive to build. Now at least I can try whatever I fancy!!

Ps: love your pocher formula 1