- Joined

- Dec 16, 2016

- Messages

- 1,020

- Points

- 493

Hello modellers. Another short update on my progress. First I received my missing cylinder head from AL. in fact they sent me a packet of four, again excellent service.

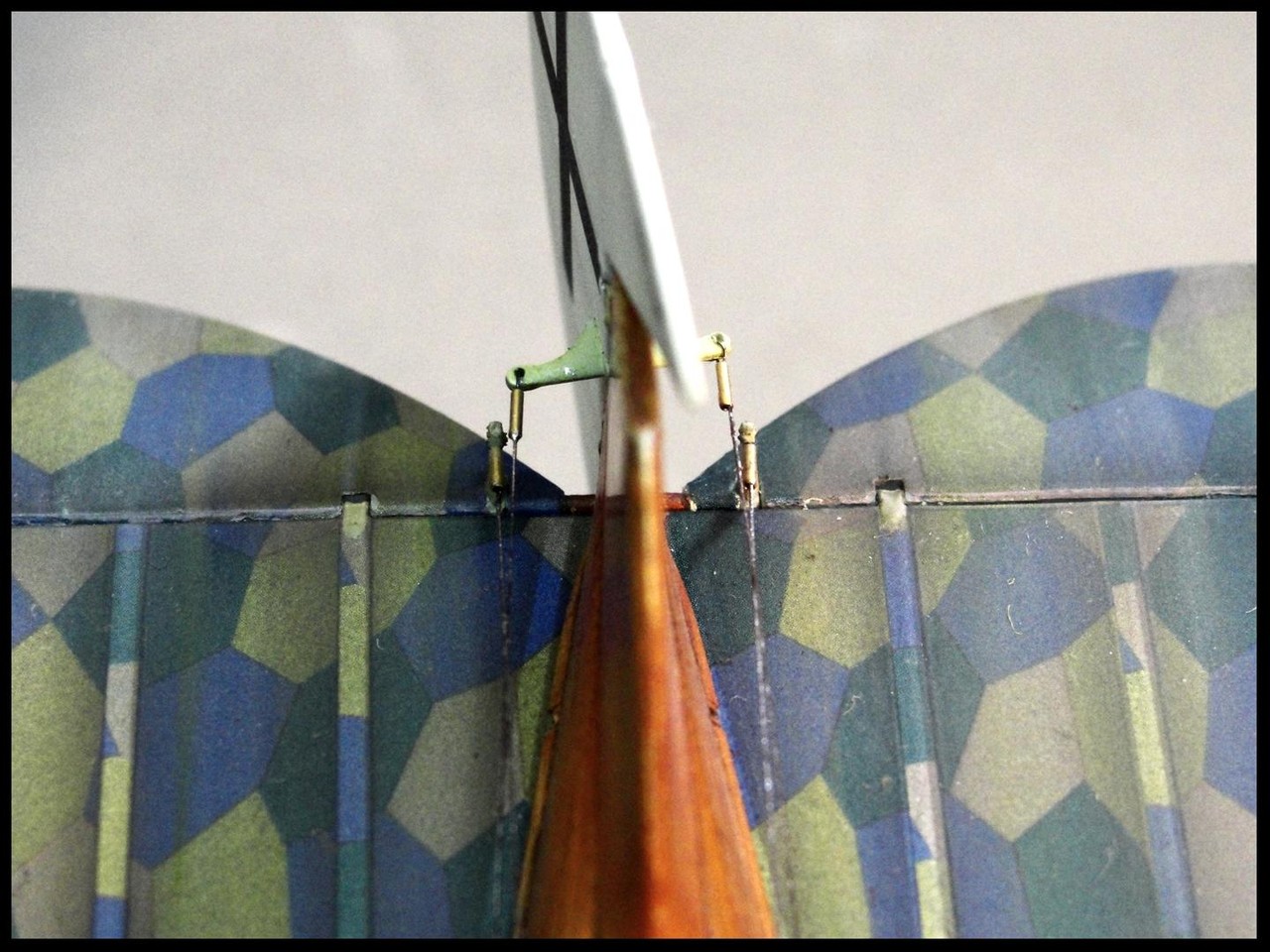

Next task should be the PE parts for the rigging, eyelets , turnbuckles etc, I know that they are going to give me nightmares so I’m putting off doing them for as long as I can, so although out of sequence I’ve started making the upper wing. Again all the parts are a very good snug fit which is making things quite easy, I’ll sand the ribs when they’re all in place, they’ll be a bit stronger then, again although fragile I still haven’t broken any.

I must tell you about these cyno application nozzles. I bought a pack off Ebay to try out and wow, they are magic, the best I’ve used and I’ve tried lots. I used them with medium viscosity, they let very small easy to control amounts through, even very small droplets, the cyno doesn’t stick to them, it is easily wiped away, when the tip finally gets blocked you just cut away a small part of the tip and they’re then as good as new, two lasted me for a whole bottle. These are very cheap and I couldn’t recommend them highly enough.

Next task should be the PE parts for the rigging, eyelets , turnbuckles etc, I know that they are going to give me nightmares so I’m putting off doing them for as long as I can, so although out of sequence I’ve started making the upper wing. Again all the parts are a very good snug fit which is making things quite easy, I’ll sand the ribs when they’re all in place, they’ll be a bit stronger then, again although fragile I still haven’t broken any.

I must tell you about these cyno application nozzles. I bought a pack off Ebay to try out and wow, they are magic, the best I’ve used and I’ve tried lots. I used them with medium viscosity, they let very small easy to control amounts through, even very small droplets, the cyno doesn’t stick to them, it is easily wiped away, when the tip finally gets blocked you just cut away a small part of the tip and they’re then as good as new, two lasted me for a whole bottle. These are very cheap and I couldn’t recommend them highly enough.