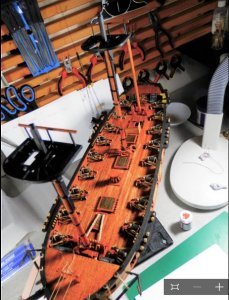

Masts. The photos show the sequence. Some points –

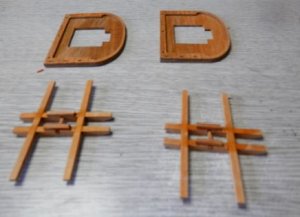

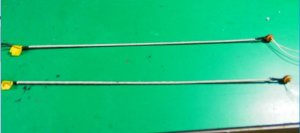

a. The top of the masts are squared off where they go through the crosstrees. I ran them across the bench grinder to take off the bulk of the material and then finished them off with a sanding stick; it worked well.

b. The banding on the masts is supposed to be achieved using black cartridge paper. I gave it my best shot but it did not look too good, so I whipped some cord around them instead.

c. The masts are suppose to be painted the ocre colour of the hull but I stained & lacquered them.

a. The top of the masts are squared off where they go through the crosstrees. I ran them across the bench grinder to take off the bulk of the material and then finished them off with a sanding stick; it worked well.

b. The banding on the masts is supposed to be achieved using black cartridge paper. I gave it my best shot but it did not look too good, so I whipped some cord around them instead.

c. The masts are suppose to be painted the ocre colour of the hull but I stained & lacquered them.